-

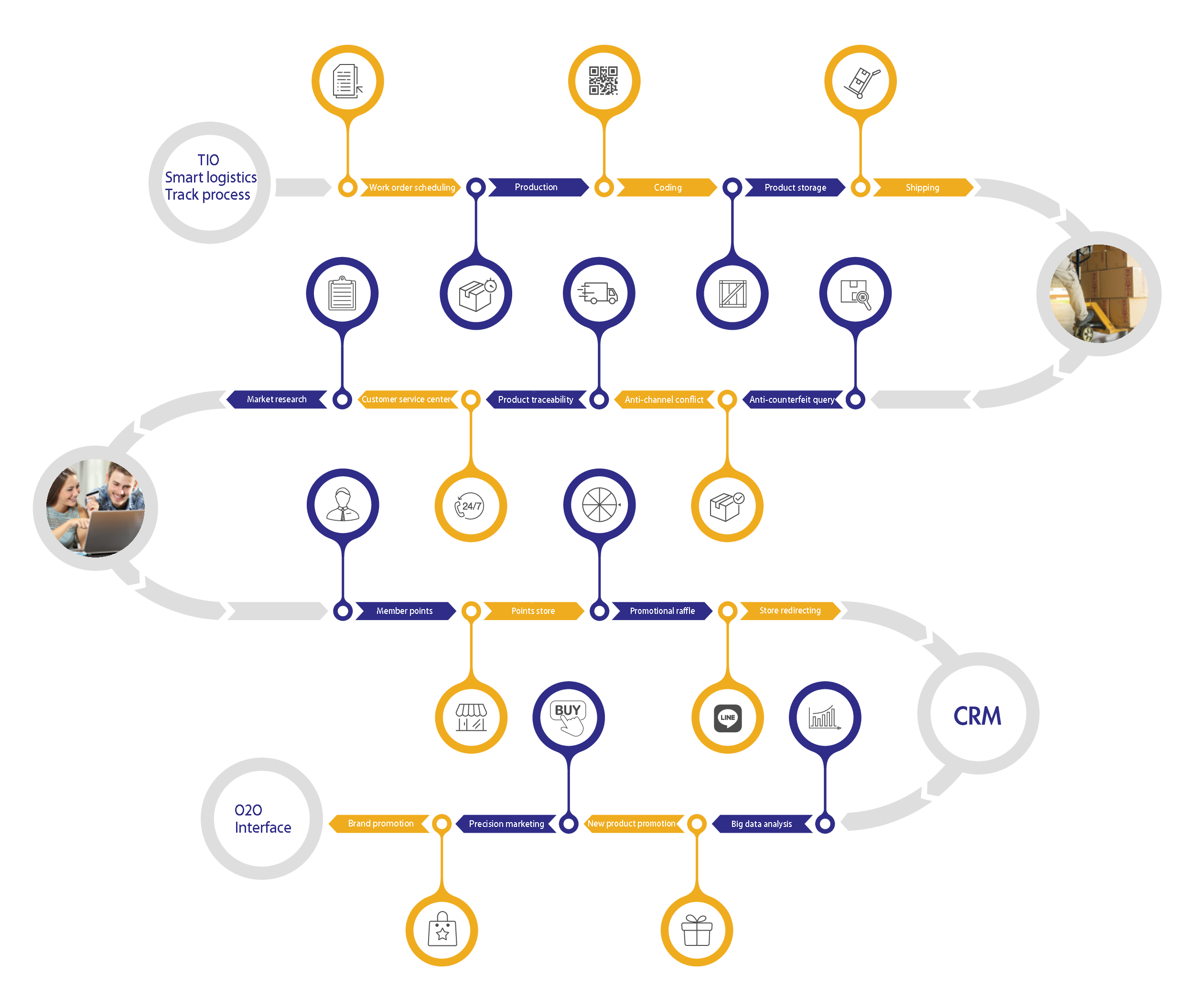

Support global deployment strategies

-

Expand a product traceability system based on GS1 standards

QR CODE

Smart Supply Chain

Management System

-

Create a decentralized global production and marketing system in line with blockchain development trends.

Our Advantage

Digitization of Factory

60% reduction in time

55% reduction in paper

Traceable System

Realize a logistics system

where everything is traceable

Central Control Software

Realize smart logistics and control risks

Coding Machine

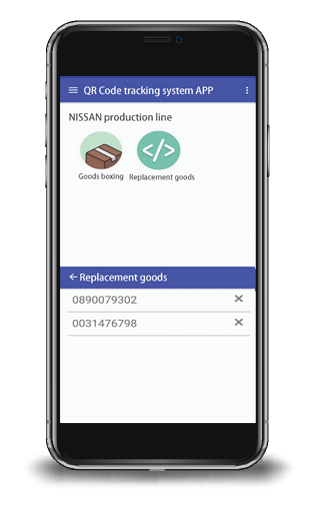

Achieve product unique QR Code through the QR Code collection process, and establish connections

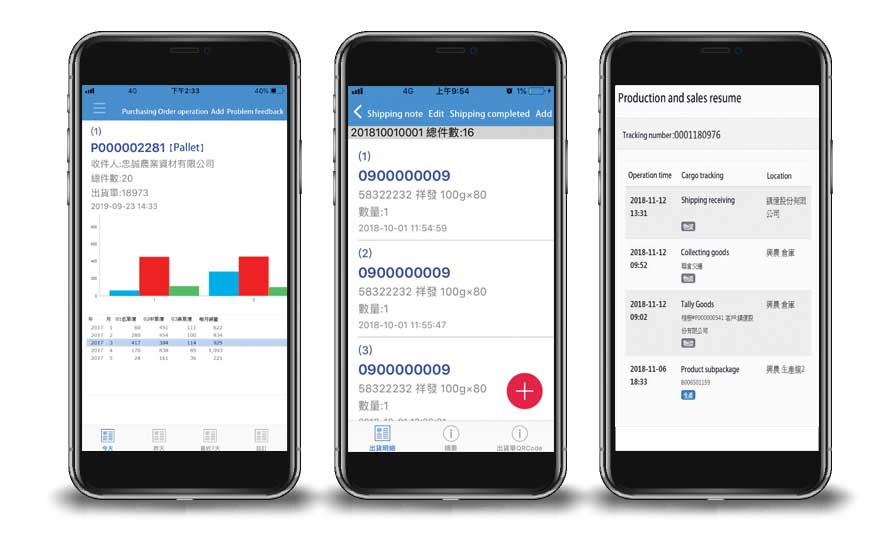

Traceable System

Schedule plan allows adjusting of production line rhythm based on actual needs of production line workers in order to achieve production operation goals

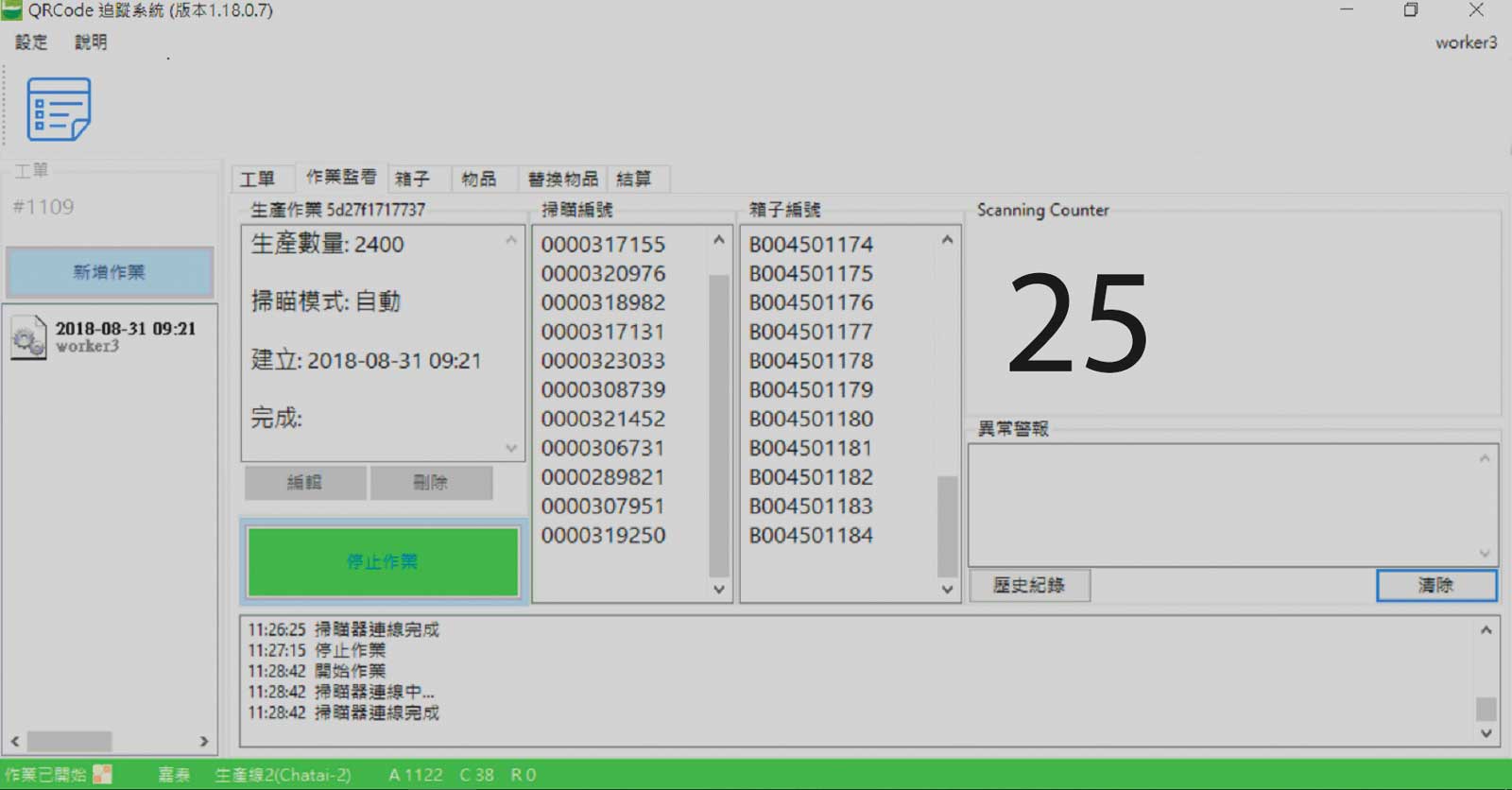

Coding Machine

Continual saving of complete production and sales information, including recording of entire production and sales information

Coding Machine

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Automatically connects to the backstage ERP work order

Digitization of factory production lines

APP system function

1.

2.

3.

4.

5.

6.

Central control software

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Realize a logistics system

Tracking process

Big data

Partner

“ Best partner”

Through the QRCODE smart supply chain system, it can truly achieve one item to one code, effectively manage time-sensitive products and effectively reduce production costs.